How to Deal with the Problems of Prestressed Concrete Strands in the Process of Tensioning?

time2021/11/04

- When the prestressed concrete strands have abnormal noise or concrete cracks during the tensioning process, we need to deal with them in time. This article will specifically introduce the solution to the tension problem of prestressed concrete strands.

We have discussed in detail the reasons for the excessive elongation of prestressed concrete strands and the occurrence of wire breakage and slippage during the stretching process in several other articles. When the following failures occur in the prestressed concrete strand, we should determine the cause of the failure in time and deal with it.

Abnormal noise during tension

During the tensioning process, I heard the sound of "boom, boom". There are three situations for making this sound. One is that the corrugated pipe ruptures and the cement slurry flows into the tunnel when the concrete is poured, and the tunnel is blocked; the other is the steel-stranded wire. Because of rust or entangled in the process of threading; there is also a gap between the anchor end extrusion sleeve and the backing plate.

The first consideration is that the corrugated pipe ruptures and the leakage causes the steel strand and concrete to form an anchor end and affects the elongation of the steel strand. Ventilate and water the bundled channel respectively and observe the air discharge and water flow.

Ventilation and water flow are very smooth, and the flow rate is relatively large. It is preliminarily judged that there is no leakage or blockage in the pores. In order to verify the preliminary judgment and clarify the reasons, it was decided to open the bundle of pores.

Aiming at the problem of steel strand winding, a 25-ton jack is used to stretch a single strand to 50% of the design stress to keep each prestressed tendon the same relaxation, and then a 250-ton jack is used to stretch to the design stress to ensure that each strand is uniform Withstand stress. After adjusting according to this method, the measured left elongation of N11-3 is 402mm, which is within ±6% of the design elongation required by the specification.

If it is the problem of cement slurry blocking the pipe, simply remove the cement slurry in the tunnel, and after stretching according to the normal procedure, use the concrete one grade higher than the design mark to block the excavated hole.

Deformation and cracking of concrete at anchor plate under anchor head

(1) The anchor pad is installed obliquely or the bell mouth is filled with concrete and eccentrically stretched. When the anchor pad is subjected to eccentric force, it will cause excessive local stress on the contact position of the anchor pad and the anchor, which exceeds the ultimate compressive strength of the concrete and causes the concrete to crack.

(2) The anchor is not installed in place and is not placed in the groove of the anchor pad. When the anchor is not placed in the groove of the anchor backing plate, the anchor and the anchor backing plate cannot fit tightly. The anchor is in an inclined state during tension, and the contact position of the anchor and the anchor backing plate will cause stress concentration, which is easy to cause anchoring The pad cracked and the concrete cracked.

(3) The concrete at the opening of the tensioning slot is not vibrated and compacted, and there is a cavity. Because the steel bars at the anchor pad are very dense and are often in a position that is difficult to reach by the vibrator, if no measures are taken, cavities will often occur. When there is a cavity in the concrete behind the anchor pad, the concrete cannot effectively share the pressure during the tensioning process, and the concrete cracks and the anchor pad cracks are very easy to occur.

(4) The spiral reinforcement under the anchor is not installed, and the mesh reinforcement under the anchor is not installed. The under-anchor spiral bars and mesh steel bars can effectively share the pressure on the anchor pad, strengthen the compressive strength of the concrete around the anchor pad, and prevent the concrete from cracking.

(5) The concrete strength does not meet the tensile strength requirements, and the tension is too early.

After observing the cracked concrete on the spot, it was determined that the concrete at the opening of the tension slot was not vibrated and compacted and could not effectively bear the pressure, causing the concrete to crack.

Tensile and loosen the anchors of the steel strands, remove the anchor pads at the tension end, chisel out and clean all the concrete with quality defects, install the anchor pads, and pour the higher-grade concrete, and wait for the strength and elasticity of the concrete Re-tension when the modulus reaches the designed tension condition.

If you want to know more about the solutions of prestressed concrete tension after reading the above, CHUNPENG can provide you with professional advice.

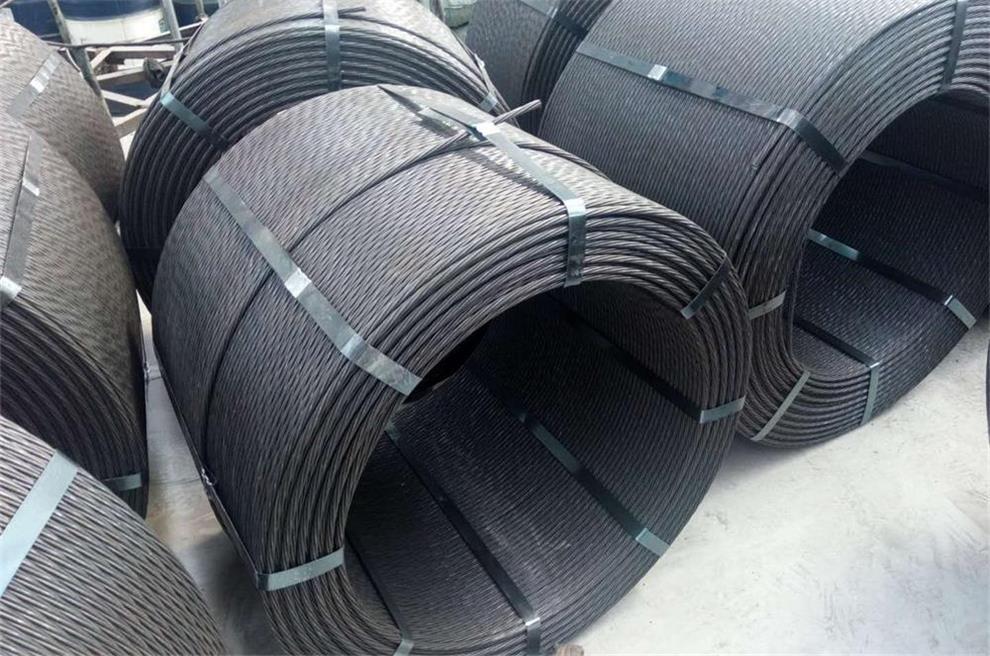

As a professional manufacturer of prestressed concrete products, we always put the needs of our customers first. Our strict quality inspection system and comprehensive management services can carry out strict quality control on the workmanship and details of the products. At the same time, we will also provide customers with thoughtful one-stop shopping services and develop effective solutions. If you want to buy our prestressed concrete strands, please contact us immediately!