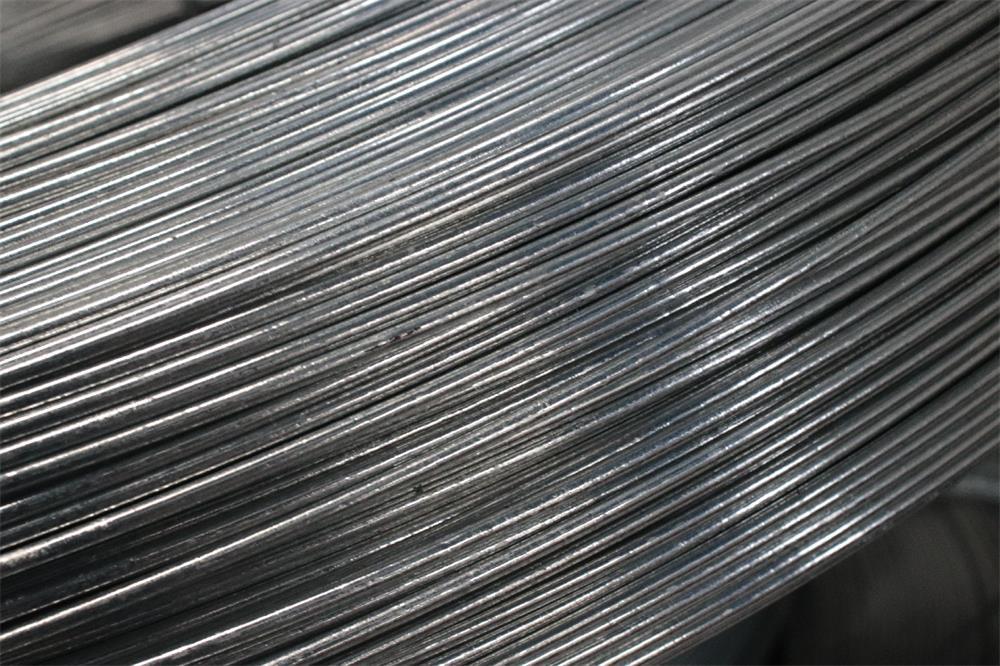

How to Achieve Various Mechanical Performance Indicators of Prestressed Concrete Steel Wire?

time2022/02/16

- This article will share the preparations for the operation of the prestressed concrete wire and the precautions in the process to achieve the various mechanical performance indicators of the prestressed concrete wire.

Through surface pickling and phosphating treatment, the oxide scale on the surface of the wire rod can be removed, and a phosphating salt layer lubricating film is formed on the surface of the wire rod, which reduces the friction between the mold and the steel wire during the drawing process and ensures the various mechanical performance indexes of steel wire products. To achieve this goal, there must be sufficient technical preparation, the following is the operating process of the prestressed steel wire.

Prepare in advance

(1) Check whether the model and variety of the wire rod meet the production specifications, and divide the whole piece of wire rod by one half, and the weight is roughly equal to about 1000-1200 kg.

(2) Check whether the flushing water is turbid, if it is turbid, replace it with clean water.

(3) Check whether the chemical dissolving acid and alkali indicators in the sulfuric acid pool and phosphating pool meet the requirements and whether the phosphating solution reaches 72-80 degrees. The acidity of the sulfuric acid in the sulfuric acid pool is appropriate (subject to the ability to remove the surface oxide scale within 15-25 minutes).

Operation process

(1) The operator divides the wire into two bundles and threaded them into the iron bars respectively. Use an electric hoist to start hoisting into the pickling tank and soak for 20 minutes, and pay attention to the degree of pickling of the steel at any time during the pickling process. In the pickling process, in order to ensure that the surface of the steel wire is soaked quickly, it can be raised and lowered. Workers should grasp the situation in a timely manner during the operation.

(2) After the oxide scale is removed, the wire enters the cleaning tank for cleaning. And repeatedly lift or slide left and right to remove surface attachments.

(3) The cleaned wire should be lifted for 2 minutes and transferred to the next process after most of the clean water is removed.

(4) Before entering the phosphating tank, you should pay attention to testing the water temperature. The temperature of the phosphating solution must be at 80 degrees Celsius. After the surface becomes grayish, lift it to dry and enter the lime pool to apply lime water for lubrication effect.

(5) The surface-treated wire should be placed in a dry place for natural drying. It is best to use a drying room to dry when possible.

(6) After finishing the surface treatment of the steel wire, put it into the predetermined place. It must not be placed in open storage or in a damp place. Should be placed in the warehouse to dry.

If you want to know more about prestressed concrete wire after reading the above, please continue to pay attention to our news.

As an experienced manufacturer of prestressed concrete products, CHUNPEN has become a leader in the industry with our excellent manufacturing technology and strict quality inspection system. We have a professional production team that fully controls the selection of products, manufacturing processes, and exports. At the same time, we will also provide thoughtful services and effective solutions according to the diverse needs of customers. If you want to buy our prestressed concrete steel wire, please contact us immediately!