How to Construct Prestressed Concrete Steel Strands in Bridge Engineering?

time2021/11/25

- Once the prestressed concrete strand is corroded, it will easily affect its own structure and performance. This article will specifically introduce the anti-corrosion method of prestressed concrete steel strands.

Because prestressed concrete strands are often used outdoors, if they are not pre-treated, the prestressed concrete strands are likely to be corroded. In order to better avoid corrosion of the prestressed concrete strands, we must deal with the following aspects.

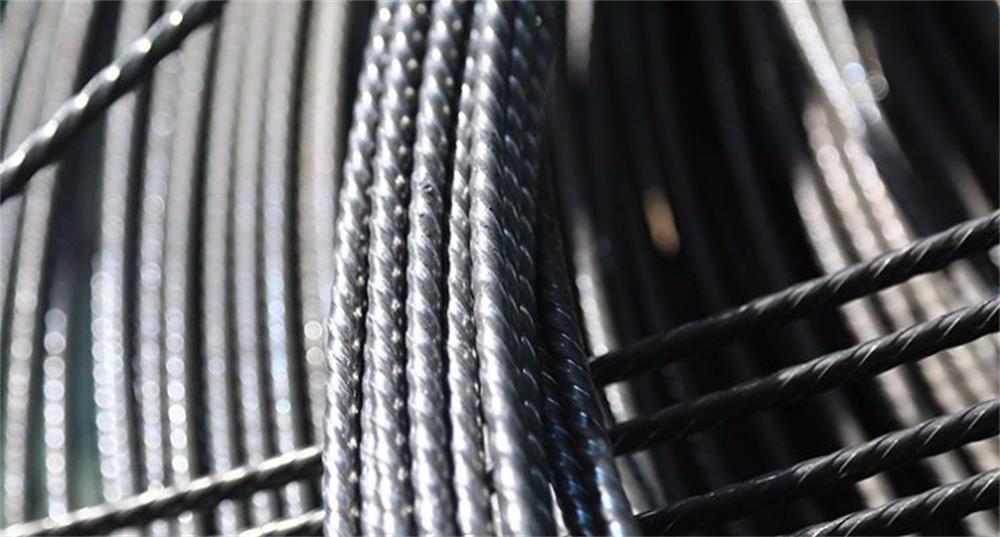

1. When the prestressed concrete steel strand is produced, the prestressed concrete steel strand will be galvanized when the steel wire is produced. That is what we often use. The galvanized steel wire can improve the quality of the material. It can effectively ensure that it will not be corroded when used in a variety of environments.

2. When the prestressed concrete strand is stored, improper preservation methods may cause corrosion of the prestressed concrete strand. The severely corroded prestressed concrete steel strands directly become waste products and cannot be used continuously, resulting in material waste. When purchasing, the sample should be selected to the relevant unit for inspection, if the inspection is qualified, it can be included in the scope of consideration for the purchase.

3. When selecting and purchasing samples, the samples should be sent to the relevant unit for inspection. If the inspection is qualified, it can be included in the scope of consideration for purchase, so that the order can be placed. After the goods arrive, you can only check whether the steel pipe anchoring is safe for each point where the prestress is used.

4. When storing prestressed concrete strands, choose a suitable warehouse with a good ventilation environment. Use concrete to harden the ground to ensure drainage. The troughs under the prestressed concrete strands should be padded with square wood. The pre-stressed concrete strands stored in batches need to be stored separately.

Clean up oil and other stains before storage. When cutting, it must be ensured that the lengths of the prestressed concrete strands are the same. Prestressed concrete strands should be used when in use, which can effectively reduce the corrosion rate of prestressed concrete strands.

5. In order to solve the common bending failure mode of prestressed concrete strands in engineering, more vertical cracks and even distribution were obtained through buckling tests. The cracks of the shear test piles are small, and the inclined cracks lag behind the vertical cracks.

Calculating the fracture strength of the specimen, as well as the results of the shear strength test and the standard formula, the h-shaped material has better ductility and deformation integrity than the results of the ultra-high-strength concrete pipe pile bending test.

6. When the quantitative effect of the fatigue life of the steel fiber is recognized, the prestressed concrete steel strands decrease sharply with the increase of the degree of corrosion, and the degree of corrosion has a greater impact on the fatigue life of the chain. Under the specified fatigue life, with the degree of corrosion increasing, the allowable stress amplitude decreases rapidly.

If you want to know more about prestressed concrete strands after reading the above, you can get a comprehensive solution by contacting us.

CHUNPENG is a professional manufacturer of prestressed concrete products. We have many years of experience and a strict quality inspection system. We uphold a responsible attitude towards users and take full control of all aspects of product manufacturing and export. At the same time, we will also provide a one-stop-shopping service according to the diverse needs of users. If you want to buy our prestressed concrete strands, please contact us immediately!